Licorice, peanut puffs, corn flakes, snack bars, breakfast cereals in all shapes and colors, pasta, crispbread, soy meat, cat and dog food, everything passes through the extruder. The extruder swallows almost everything and converts cheap raw materials into expensive products. But who knows this magic machine, responsible for a number of groceries that have found their way to the shelves of our supermarkets?

Slowly the semolina pulp sinks into the funnel of the extruder. Underneath, inside a metal sleeve, a steel spiral is turning, soaking up the nutritious mass and pushing it forward. It’s getting tighter. Huge shear and pressure forces mercilessly move the pulp forward. He’s getting hotter and hotter. At the end of the pipe, the mass is passing with high pressure through a nozzle. Suddenly the mass is released, water evaporates and the pulp puffs up. Rotating knives cut the airy mass into the desired shape. Vitamins that fell by the wayside during this procedure are injected from fine nozzles. Ready are your breakfast cereals!

History of the Extruder

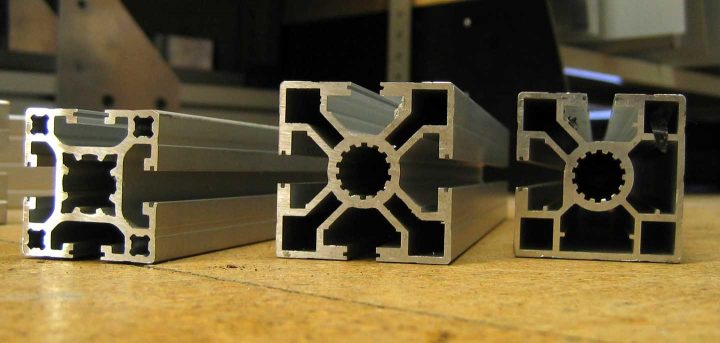

According to the dictionary, extrusion means: “To express a product through a nozzle, a hole or a slot in order to obtain a certain shape.” The first products to come out of an extruder were seamless lead pipes. Today, a wide variety of plastic pipes and profiles are made, but also bricks, copper wires, coated wires, soaps and much more are pressed through the extruder.

It wasn’t long before the food industry discovered the extruder for its own purposes. In 1869, pieces of meat were squeezed through the machine and stuffed into sausage skins. The extruder is indeed reminiscent of the good old meat grinder. The extrusion principle has already for a long time been used in pasta processing. Hydraulically driven piston presses squeeze moistened semolina through perforated plates, forming spaghetti, macaroni, spirals, stars and letters. Roller extruders and piston presses also transform sugar masses in the confectionery industry into all conceivable shapes and forms.

With the introduction of the screw extruder in the pasta industry during the mid-1930s, began the modern age of the extrusion process in food technology.

Structure of the Cooking Extruder

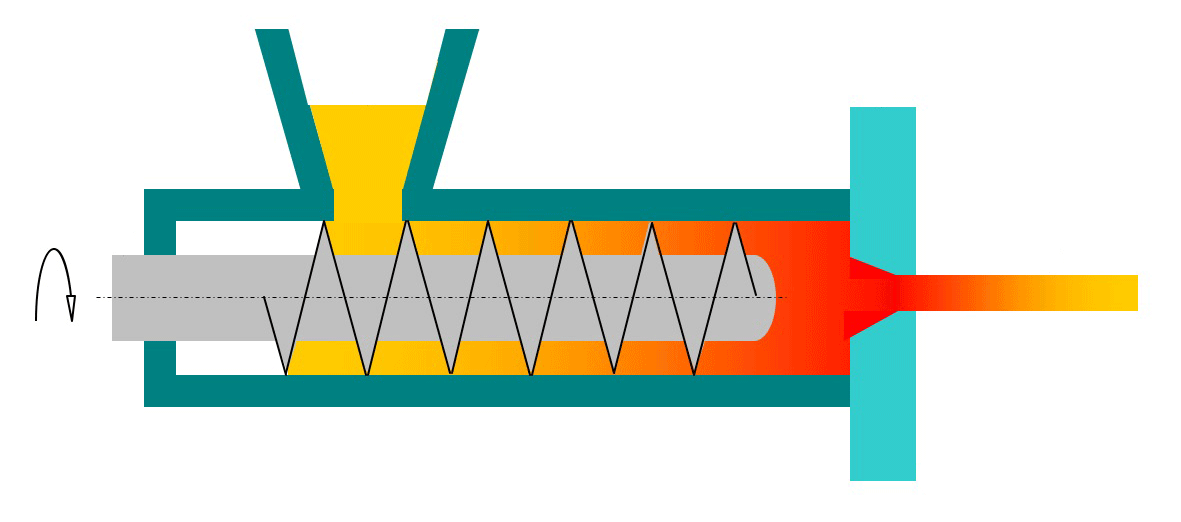

In simple terms, each extruder can be divided into the following parts. First comes the feeding zone, comparable to a funnel. This is where the raw material, be it flour, semolina, a porridge, ground peanuts, starch or a sugar mass, is fed in. A screw, sometimes two co-rotating or counter-rotating screws, transport the mass forward.

This is followed by the conversion zone. This is where things are mixed, compressed, heated, melted, transformed. Mechanical and thermal reactions take place. That is why the extruder is sometimes referred to as a bioreactor.

Now the processed product comes to the discharge zone. A nozzle is the limit. The nozzle and subsequent rotating knives determine the shape of the product to a wide extent. When the heated mass is pressed through the nozzle, the water in the product evaporates abruptly due to the drop in pressure. It results in a blown-up product, giving it a porous, light an airy structure. In principle, extruding mimics the conventional production of popcorn. Popcorn puffs at around 9.5 bar and at a temperature of about 350⁰F (175⁰ Celsius).

The Result: Product Diversity

The extruder swallows almost everything, whether waste products or valuable raw materials. Depending on the process, dry raw materials, moistened or pulpy masses are processed. Often the heat generated by the shear forces and pressure alone is enough to transform the material into the desired shape. This is referred to as cold extrusion. The friction normally results in temperatures of 90 to 140⁰F (40 to 60⁰C). However, there are also processes where additional heat must be added. The warm extruder works with 160 to 270⁰F (70 – 130⁰C) and the hot extruder with 270 to 480⁰F (130 – 250⁰C). Most cooking extruders are based on combinations of frictional heat and externally supplied heat. The pressure is in the range up to 200 bar.

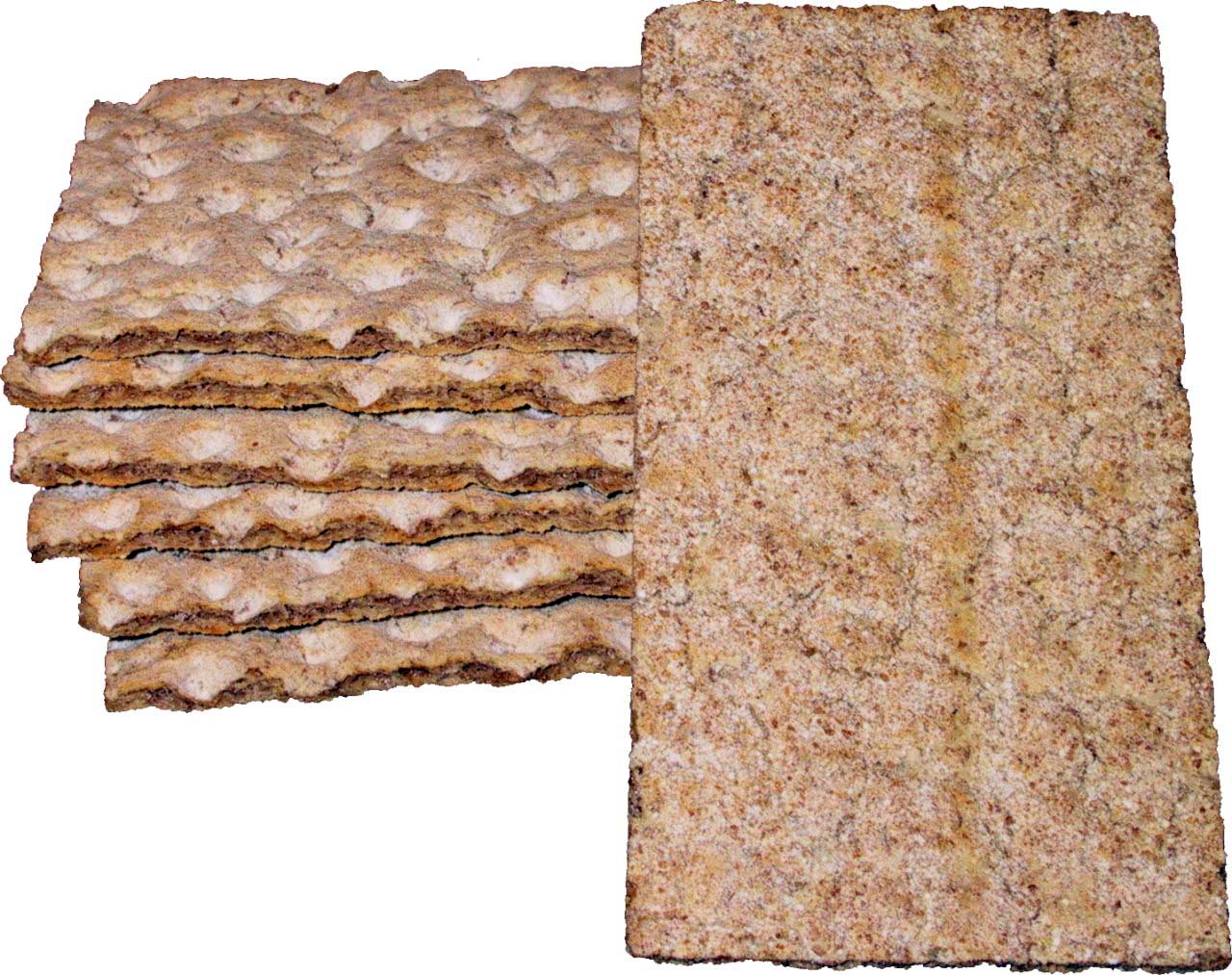

The variety of products from the extruder is overwhelming. Many conventional baking or cooking processes are replaced by the extruder. Today, almost all breakfast cereals come from the extruder. A new generation of crispbread has emerged. It has an airy, light, longitudinal fiber structure.

Milling waste products such as bran and grinding meal are refined in the extruder, given new structures and afterwards are added to baked goods. Breadcrumbs and modified starch, as well as many instant foods, such as instant soups, are now produced in the extruder. Oil can be extracted. Chewing gum and even chocolates are made in the extruder. A lack of taste, due to the fast production or less valuable raw materials needs to be compensated by many tricks and trade secrets of the industry.

An interesting product is also the long egg. Boiled, sliced eggs are used a lot for garnishing. For practicality, egg yolk and egg white are separated and cleverly reassembled in the extruder. The end product is a meter-long rod, in which the yolk is always nicely placed in the middle of the egg white. There is no waste when slicing.

What Happens to the Nutrients?

The starch from raw products is almost completely broken down, so it becomes easily digestible. It comes to gelatinization and swelling, sometimes also to undesired roasting processes.

Little is known about the conversion of protein in the extruder. However, it is known that some important amino acids are destroyed. At the other hand, it has been shown that harmful enzymes in legumes, such as trypsin inhibitors in the soybean, are rendered harmless by the heat. The changes in extrusion are very versatile and can only be investigated in very complex and expensive processes. That is why there are not yet many independent results about adverse side effects of the extrusion process.

Losses are partially reduced because mass is only exposed to the high temperatures for a short time. Nevertheless, the high heat causes a substantial loss of vitamins. Cereal products provide us with the important vitamins of the B group and with folic acid. Depending on the process, there are losses of 50 – 80%. In comparison, with normal bread baking, the losses of B vitamins are between 5 and 30%. Nutrition experts recommend treating the raw materials as gently as possible. What happens in the extruder can certainly not be described as gentle. That’s why the breakfast cereals need to be subsequently enriched with vitamins.

Conclusion

Extruder products have become an integral part of our diet. Children especially demand them frequently. Be it in the form of snacks, sweets, snack bars, or breakfast cereals. But we would do well to limit it. In a nutshell, extruder products are mostly air that is sold with a lofty price tag. Expensive products are made from cheap raw materials. In case of doubt, the food industry will pay attention to the taste the consumer will crave for and less to the nutritional value that contributes to a healthy lifestyle.

If we put extruder products on the table, we should definitely vary them with conventional cereal products, in addition to fresh, untreated fruits and vegetables, nuts, and seeds. They are the ones who provide our body with important nutrients for our health.

Stay Always Up to Date

Sign up to our newsletter and stay always informed with news and tips around your health.

Esther Neumann studied Nutrition at the University of Vienna. Since then she served as an author for the health magazine “Leben und Gesundheit” and conducted health lectures in various locations of Austria.

Leave a Reply